Intelligent security management system is a new type of modern security management system, which combines microcomputer automatic identification technology and modern security management measures as a whole, it involves electronics, machinery, optics, computer technology, communication technology, biotechnology and many other new technologies. It is an effective measure to solve the problem of security management of the important department entrance and exit.

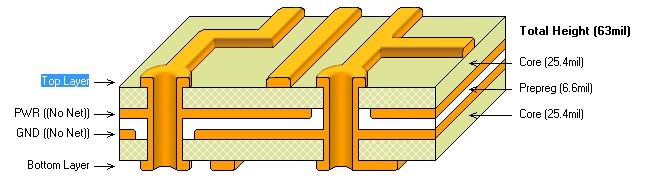

●PCB Layering Strategy

From the perspective of signal alignment, a good layering strategy would be to place all signal alignments in one or more layers that are adjacent to the power or ground layers. For the power supply, a good layering strategy should be the power supply layer adjacent to the ground layer, and the distance between the power supply layer and the ground layer is as small as possible, which is what we call "layering" strategy.

●Excellent PCB layering strategies are as follows:

1. The projection plane of the wiring layer should be within the area of its reflow plane layer. If the wiring layer is not in the projected area of the reflow plane layer, there will be signal lines outside the projected area when wiring, leading to "edge radiation" problem, and also lead to an increase in the area of the signal loop, resulting in an increase in the differential mode radiation. 2.

2. Avoid setting up wiring layers adjacent to each other. Because parallel signal alignments on adjacent wiring layers can lead to signal crosstalk, if it is impossible to avoid adjacent wiring layers, the layer spacing between the two wiring layers should be increased appropriately, and the layer spacing between the wiring layers and their signal loops should be reduced.

3. Neighbouring planar layers should avoid overlapping projection planes. Because the projection overlap, layer to layer coupling capacitance will lead to the noise between the layers coupled to each other.

●First, the top bottom pad layer of the PCB board layer:

Top paste and bottom paste is the top bottom pad layer, it is that we can see the exposed copper platinum, (for example, we drew a wire in the top wiring layer, this wire we see on the PCB is just a line, it is covered by the entire green oil, but we are in the position of this line on the top paste layer to draw a square, or A point, played out on the board this square and this point will not have green oil, but copper platinum.

Top solder and bottom solder these two layers just and the previous two layers on the contrary, so to speak, these two layers is to cover the green oil layer, solder: solder paste: paste, paste mask: cover, film, surface layer, etc. Simple to top layer as an example to speak: solder layer in protel 99SE in the full name is top solder mask, meaning that the solder resist layer, according to the literal meaning to understand is to the pcb alignment on a layer of green oil, to achieve the purpose of solder resistance, in fact, not, in the alignment if you do not add a layer of solder in the alignment, the green oil in the production of pcb manufacturers there is a default to be added, if you add a layer of solder, the pcb in the made out of the pcb, here you will see the bare Copper foil. Can be understood as a mirror phase.

●Second, the past layer is in the pcb patch before doing the stencil, used to paint the solder paste, patch the electronic components pasted on the solder paste for reflow soldering Drill-Guide and Drill-Drawing difference: 1, Drill-Guide is used to guide the drilling of holes with, C8051 chip decryption, mainly used for manual drilling in order to locate 2, Drill-Drawing is used to view the drilled hole diameter in the manual drilling, these two files to be used in conjunction. However, now most of them are CNC drilling, so these two layers are not very useful. In the placement of positioning holes do not have to deliberately place the contents of the two layers, as long as the Michanical or TOPLAYER or bottom-layer layer on the corresponding aperture can be placed over the hole through the pads, only must not be placed on the disc diameter of some small. As for the Michanical and MultiLayer the two layers are such: 1, Michanical is a mechanical layer, used to place mechanical graphics, such as the shape of the PCB, etc. 2, MultiLayer can be called multilayer, in this layer placed on the graphics in any layer has the corresponding graphics, and is not screen printed on the solder mask keep out layer in fact is not used to draw the shape of the PCB. The keep out layer is not used to draw the PCB shape, the real purpose of the keep out layer is used to prohibit wiring, that is to say, after placing a graphic on the keep out layer, there will be no corresponding graphic on the wiring layer (e.g., top layer and bottom layer) at the corresponding position of the copper foil appears, and all the wiring layer. This is not the case with Michanical layers.

●Third, the mechanical layer is to define the appearance of the entire PCB board, in fact, we are talking about the mechanical layer is to refer to the entire PCB board shape structure. Prohibited wiring layer is defined in our cloth electrical characteristics of copper a boundary, that is to say, we first defined the prohibited wiring layer, we are in the process of the cloth in the future, the cloth with electrical characteristics of the line is impossible to exceed the boundary of the prohibited wiring layer. Top overlay and bottom overlay is the definition of the top and bottom of the silk screen characters, that is, in general we see on the PCB board Component number and some characters. Top paste and bottom paste is the top bottom pad layer, it means we can see the exposed copper platinum, (for example, we drew a wire in the top wiring layer, this wire we see on the PCB is just a wire, it is covered by the whole green oil, but we are in the position of this line on the top paste layer to draw a square, or a square, or a square. But we draw a square or a point on the top paste layer at the location of this line, the board played out on this square and this point there is no green oil, but the copper platinum. Top solder and bottom solder these two layers just and the previous two layers on the contrary, can be said that these two layers is to cover the green oil layer, multilaye this layer is actually almost the same as the mechanical layer, as the name suggests, this layer is all the layers of the PCB board. Is to refer to all the layers of the PCB board.

Contact: Ella Ouyang

Phone: 86-13570888065

Tel: 86-0755-28632299

Email: ellaouyang@szxpcba.com

Add: Building 8, Gangbei Industrial Zone, Huangtian, Xixiang, Bao’an District, Shenzhen, China.

We chat