PCBA testing is a series of test activities performed on a completed assembled Printed Circuit Board Assembly (PCBA, Printed Circuit Board Assembly) to ensure that it meets the design requirements and has good functionality and performance. The following are the main elements of PCB & PCBA testing:

● Visual inspection:

Use the naked eye to inspect the PCBA to ensure that there are no obvious assembly errors, short circuits, misalignments and other problems.

● X-ray Inspection (X-ray Inspection):

Used to check the soldering of devices such as BGA (Ball Grid Array) to ensure the quality of the solder joints.

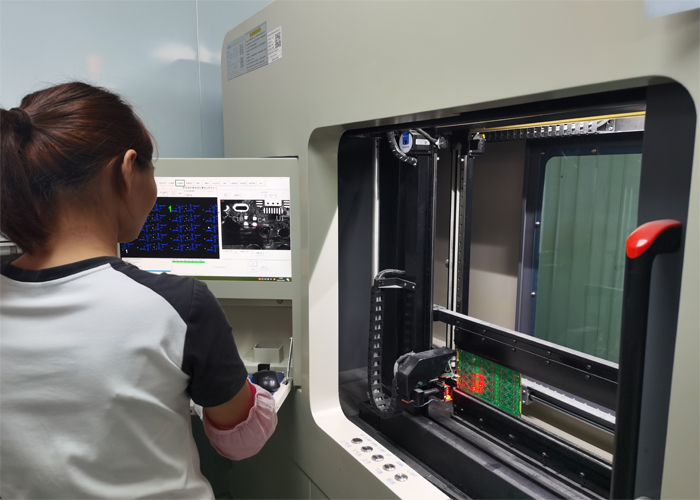

● Automatic Optical Inspection (AOI, Automated Optical Inspection):

Uses automated optical equipment to check component position, polarity, correctness and solder quality of PCBAs.

● Online test ICT

Through the test probe contact PCB layout out of the test point to detect PCBA line open circuit, short circuit, all parts of the fault situation.

● Flying probe test

It is possible to detect the value of unenergised components, open or short circuits, measure voltages and check the position of diodes and transistors.

● Function test:

Perform functional tests on PCBAs on test benches or specialised test equipment to verify that they work as designed and expected.

● Electrical Testing:

Test the circuitry of the PCBA using a multimeter or other measuring equipment to ensure that individual components and connections meet specifications.

● Communication interface testing:

If the PCBA contains communication interfaces (e.g., UART, SPI, I2C, etc.), you need to test the communication functions of these interfaces.

● Analogue signal test:

If the PCBA contains analogue circuits, you need to test the analogue signals for voltage, current and other parameters.

● High/low temperature test:

PCBAs are tested in high and low temperature environments to ensure that they can function properly under extreme conditions.

● Environmental testing:

Tests the stability and reliability of PCBAs under different humidity, vibration, shock and other environmental conditions.

● Electromagnetic interference (EMI)/Radio Frequency Interference (RFI) test:

Checks whether the PCBA meets the EMC requirements to avoid generating interference or being subject to external interference.

● Software/firmware loading and testing:

If the PCBA contains programmable devices (e.g. microcontrollers), the corresponding software or firmware needs to be loaded and tested for functionality.

● Safety certification testing:

Depending on the regulations and standards in your region, safety certification testing may be required, such as CE certification, UL certification, etc.

● Records and documentation:

Record all test results, including passed and failed items, for future reference.

● Repair and retest:

If problems are found during testing, they may need to be repaired and retested accordingly.

Contact: Ella Ouyang

Phone: 86-13570888065

Tel: 86-0755-28632299

Email: ellaouyang@szxpcba.com

Add: Building 8, Gangbei Industrial Zone, Huangtian, Xixiang, Bao’an District, Shenzhen, China.

We chat