The main working component of the LED lamp is the PCB board, and in order to adapt to the characteristics of the lamp heat dissipation, people use aluminum based board as the main board of the LED lamp, aluminum based board heat dissipation characteristics are particularly good, increase the service life of the lamp, and more energy saving than the traditional incandescent lamp. Thus, since entering the 21st century, LED lights have completely replaced traditional lamps.

●LED industry can be divided into backlight LED screen and direct display LED screen; according to the display precision can be divided into small-pitch LED, Mini LED, and Micro LED. compared with the traditional LED display screen, small-pitch LED display screen brings the industry to a higher resolution application market, making the whole market maintain a high growth rate from the outdoor scene to indoor applications.

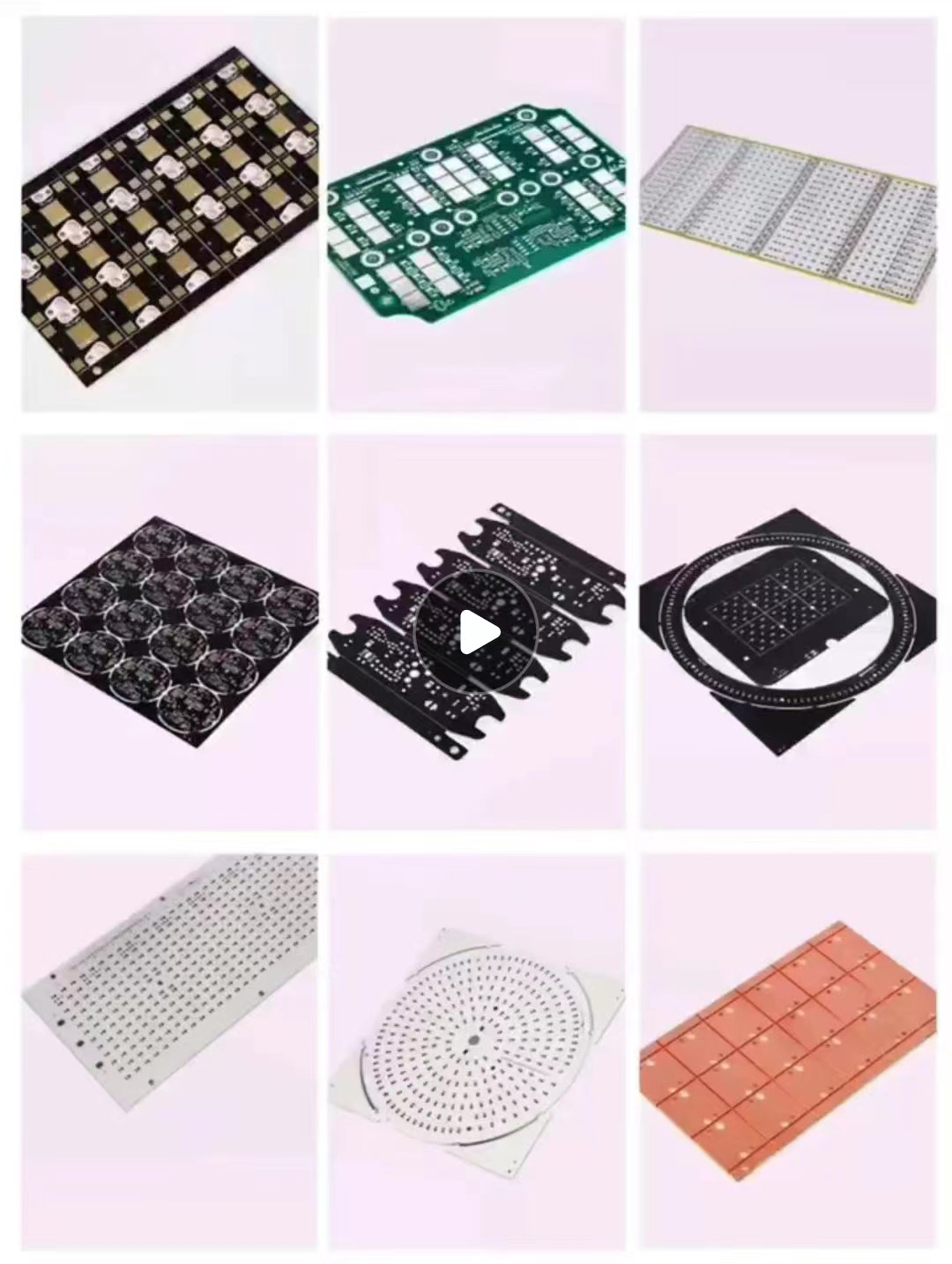

●Aluminium substrate, a metal-based heat dissipation PCB (including aluminium substrate, copper substrate, iron substrate) is a low-alloyed Al-Mg-Si system of high-plasticity alloy plate, which has good thermal conductivity, electrical insulation properties and machinability, aluminium substrate and the traditional FR-4 compared to the use of the same thickness, the same line width, the aluminium substrate is able to carry higher currents, aluminium substrate voltage up to 4500V, thermal conductivity greater than 2.0, the industry is dominated by aluminium substrates.

-The use of surface mount technology (SMT);

-Extremely effective treatment of heat diffusion in circuit design schemes;

-Reducing product operating temperatures, increasing product power density and reliability, and extending product life;

-Reducing product size, reducing hardware and assembly costs;

-Replacing fragile ceramic substrates for better mechanical durability.

●It is structured in three layers

┃Cireuitl.Layer: Equivalent to the copper cladding of an ordinary PCB, the line copper foil thickness loz to 10oz.

┃DielcctricLayer: The insulation layer is a layer of low thermal resistance thermally conductive insulation material. Thickness: 0.003" to 0.006" inches is the core technology of aluminium-based copper-clad laminates, which have been certified by UL.

┃BaseLayer: is a metal substrate, generally aluminium or optional copper. Aluminium-based copper-clad laminates and traditional epoxy glass cloth laminates.

●Aluminium substrate pcb's application.

1.Automobile: electronic regulator, ignition, power controller, etc.

2.Computer: CPU board, floppy drive, power supply unit, etc..

3. LED lighting: LED display, LED lamps and lanterns.

4.Power modules: converters, solid state relays, rectifier bridges, etc.

5.Power equipment: switching regulator, DC/AC converter, SW regulator, etc.

6. Audio equipment: input and output amplifiers, balanced amplifiers, audio amplifiers, preamplifiers, power amplifiers.

7. Communication electronic equipment: high-frequency amplifier, filtering appliances, sending circuit.

8. Office automation equipment: motor driver, etc..

●Advantages of aluminium PCB:

1. Heat dissipation: High temperatures can cause serious damage to electronic equipment, so it is wise to use materials that help dissipate heat. In fact, aluminium transfers heat from vital components, thus minimising its harmful effects on circuit boards;

2. Environmentally friendly: aluminium is non-toxic and recyclable. The use of aluminium also helps to save energy due to its ease of assembly. For PCB suppliers, the use of this metal helps keep the planet healthy;

3. Lightweight: Aluminium has incredible durability and is an amazingly light metal. Aluminium adds strength and flexibility without adding any extra weight;

4. Greater durability: aluminium provides strength and durability to products that ceramic or fibreglass substrates cannot. Aluminium is a solid substrate that reduces accidental damage during manufacturing, handling and everyday use.

Contact: Ella Ouyang

Phone: 86-13570888065

Tel: 86-0755-28632299

Email: ellaouyang@szxpcba.com

Add: Building 8, Gangbei Industrial Zone, Huangtian, Xixiang, Bao’an District, Shenzhen, China.

We chat