Automatic control devices, industrial robots, intelligent complete sets of equipment and other rapid development. The wave of industrial control system networking also integrates such popular technologies as embedded technology, multi-standard industrial control network interconnection, wireless technology, etc., thus expanding the development space of the industrial control field and injecting new development opportunities for the PCB industry.

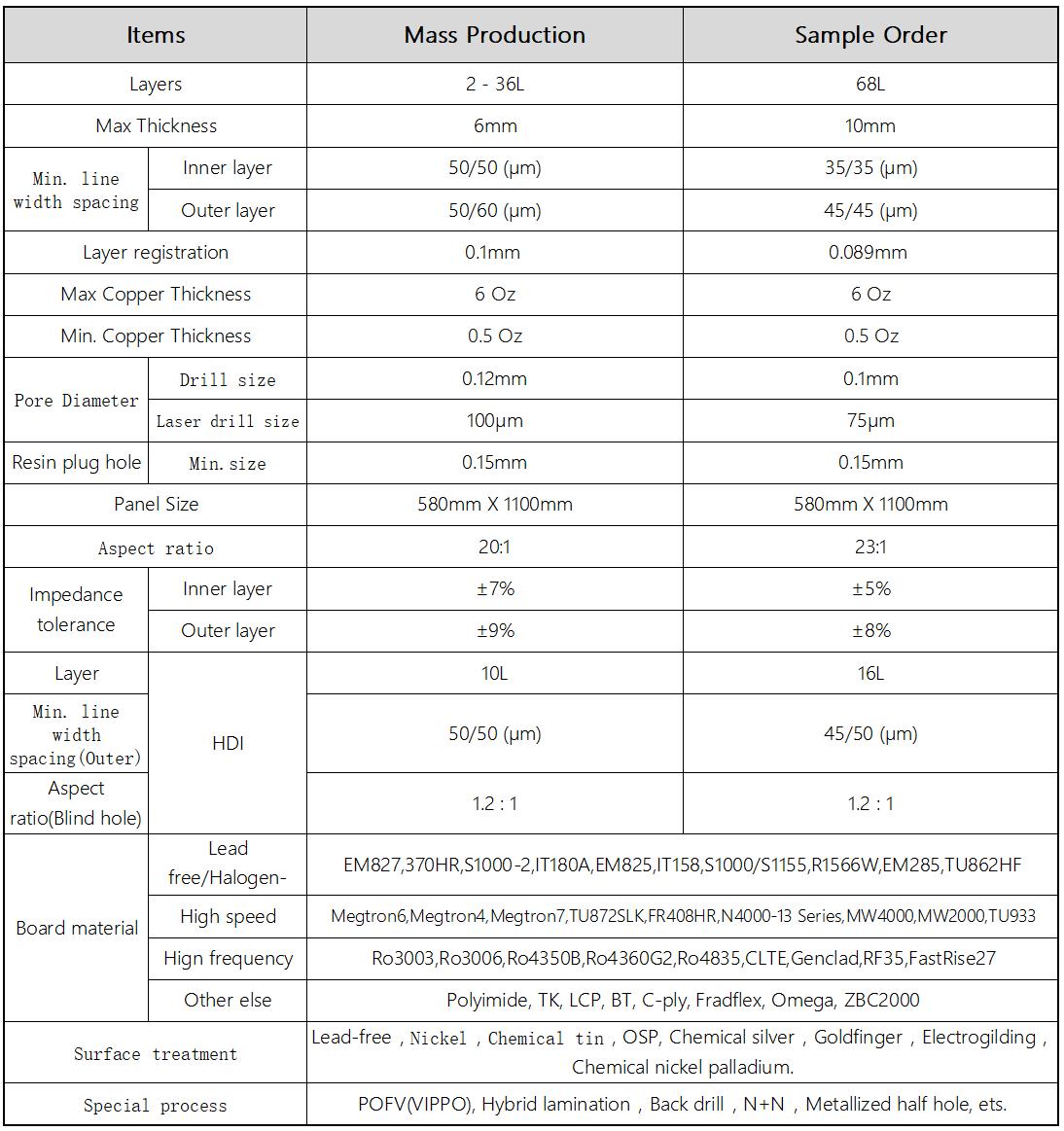

Our Process capacity of PCB

●What is an Industrial PCB?

Industrial PCBs are PCBs used in industrial production areas with high reliability, stability and durability. Industrial PCBs are widely used in various fields such as power supply units, robots, electronic switches, gears, industrial drives and inverters, electronic test and measurement equipment, energy control systems, industrial smart meters, electronic smart labels, and industrial lighting systems.

Electronic devices used in industrial applications need to be extremely stable and durable to withstand extremely harsh conditions while maintaining a long lifespan. Industrial PCB design and industrial printed circuit board manufacturing also need to follow strict industrial SIL and IEC standards and create unique design features and profiles for any industrial environment.

Shock, vibration, temperature extremes, humidity and dust control issues in industrial PCB design can be addressed by paying attention to materials and processes during PCB production.

●What are the requirements for industrial control PCBs?

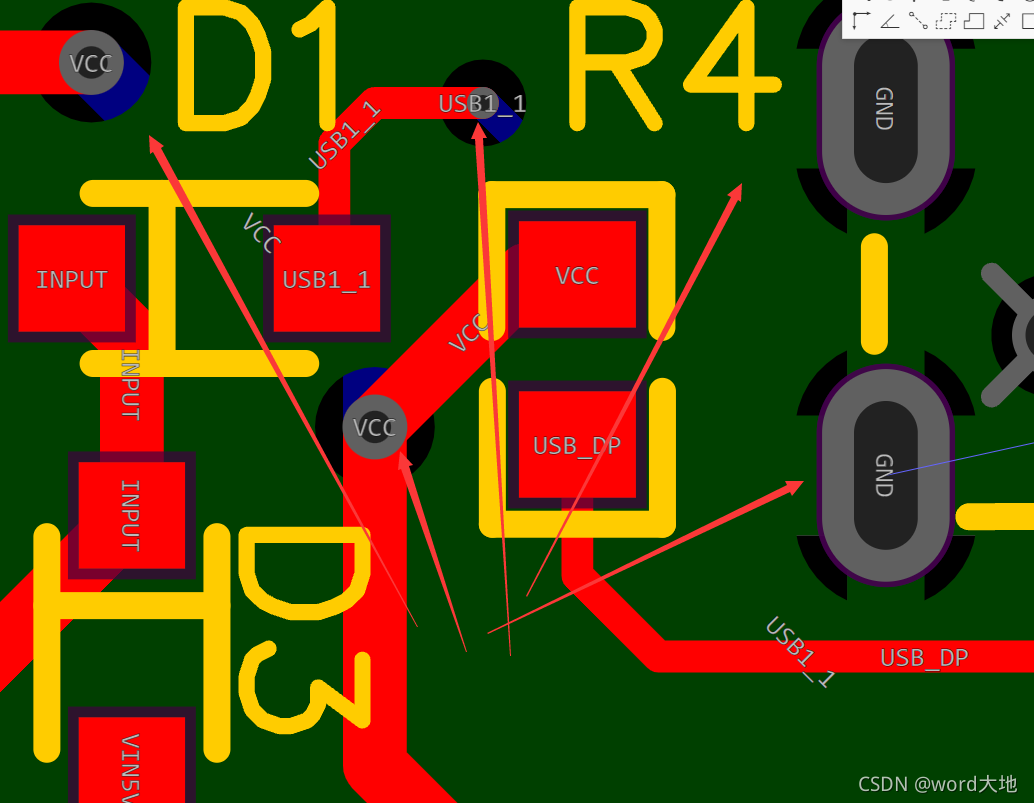

1, Industrial control PCB circuit board layout:

Before setting up the industrial control PCB circuit board alignment, the first step is to determine the layout of the circuit board. Through the layout of the arrangement can make the alignment more reasonable, which is conducive to reducing circuit noise and interference. When determining the layout, it is also necessary to consider the location of electronic components and wiring methods.

2. Set the ground of the industrial control PCB circuit board:

The ground setting of the industrial control PCB circuit board is very important to avoid interference from the earth wire. The ground of each electronic component should be wired at the same nearest ground point to reduce the voltage difference between the wires. In addition, the earth wire should be connected to the ground point of the board for better stability of the industrial control PCB circuit board.

3. Industrial control PCB circuit board power lines:

The design of the power supply line must be reasonable, the working stability of the industrial control PCB circuit board can be better. In the design of the power supply line, you need to consider the location of the input and output capacitors to ensure that the capacitors through the line in the form of a good protection of industrial control PCB circuit boards.

4, Industrial control PCB circuit board line width line spacing is appropriate:

Industrial control PCB circuit board line width line spacing is not set up reasonably will affect the flow of current, thus affecting the stability of the circuit board; if the spacing is too large, it will lead to the circuit board noise. To solve this problem, the design should be industrial control PCB circuit board line width line spacing distance as narrow as possible, and the use of appropriate insulation layer for insulation.

5, Industrial control PCB circuit board alignment thickness:

Industrial control PCB circuit board alignment thickness is directly affect the heat of the circuit board, if the alignment thickness is too large will affect the thermal conductivity of the circuit board. Therefore, the circuit board alignment thickness should be controlled according to the power size and board area size. In the design of the alignment, should also be based on specific requirements to choose the appropriate width of the alignment.

●Industrial PCB products are widely used in the following areas:

Power supply units

Robotics

Electronic switch gears

Industrial drives and inverters

Electronic test and measurement equipment

Energy control systems

Industrial Smart Meters

Electronic smart labels

Industrial Lighting Systems

●Main features of industrial PCB:

High reliability: industrial PCB has high reliability and stability after strict quality control and testing, which can ensure long time normal operation and less failure.

Strong durability: industrial PCB selects high-quality materials and manufacturing process, has a longer service life and lower damage rate.

Strong anti-interference: industrial PCB has good anti-interference performance, can effectively prevent the impact of external interference on the circuit, to ensure the stable operation of electronic equipment.

High safety: industrial PCB has good safety performance, can prevent circuit overheating, overcurrent, overvoltage and other dangerous situations, to protect the safety of industrial production.

Economy: Although the price of industrial PCB is higher than commercial PCB, but its long life, less maintenance, high efficiency, has a better economy.

In short, industrial PCB in the design and production process need to follow strict quality control and safety specifications, with high reliability, durability, anti-interference, safety and economy, etc., to meet the needs of a variety of harsh environments and industrial production.

Contact: Ella Ouyang

Phone: 86-13570888065

Tel: 86-0755-28632299

Email: ellaouyang@szxpcba.com

Add: Building 8, Gangbei Industrial Zone, Huangtian, Xixiang, Bao’an District, Shenzhen, China.

We chat